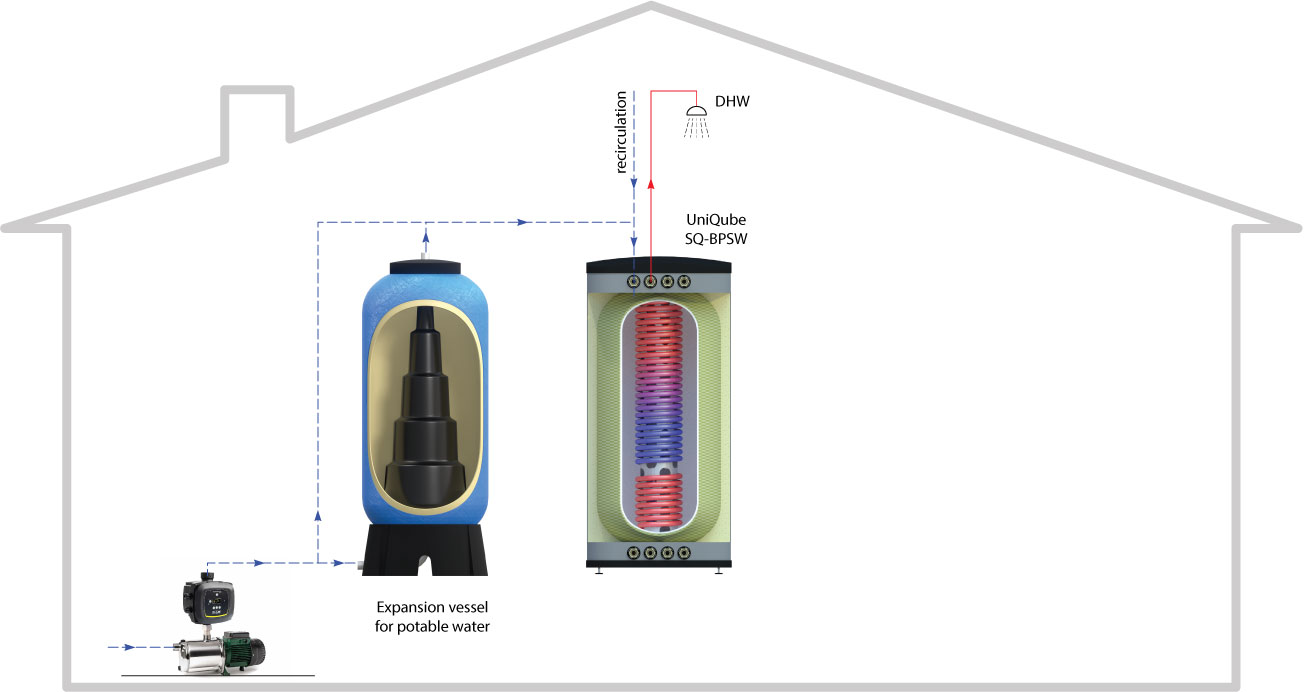

Composite Expansion Vessels for Potable Water Systems

Ensures constant water flow

Composite Expansion Vessels for Potable Water Systems

Technical characteristics

- Approved in accordance with pressure equipment guidelines 2014/68/EU

- Pressurized gas chamber

- Replaceable membrane

- Dimensions of top and bottom connectors may be changed on request

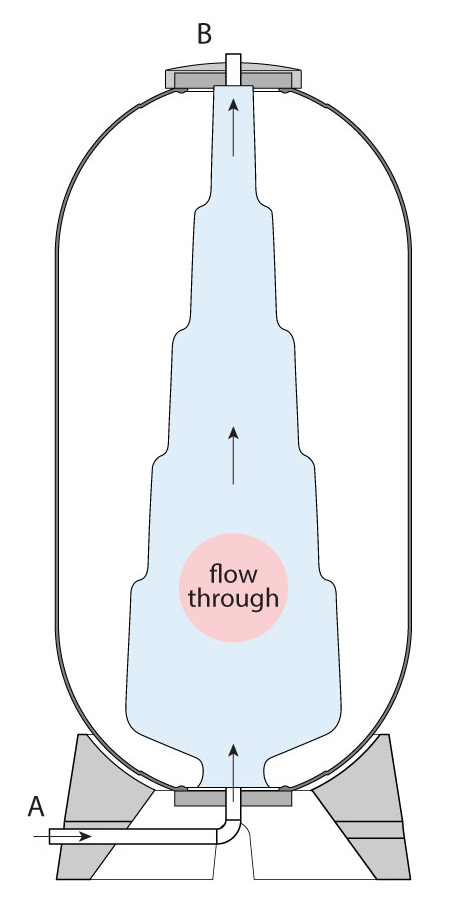

- For potable water, pressure booster systems with or without flow-through

- With threaded connection, made from corrosion-resistant steel

Plastic-composite expansion vessels for potable water

Potable water systems must be supported by expansion/pressure vessel that stabilizes the hydronic system operation, and must assure water cleanness. The flow-through type is the best option in this case. Bladder type of potable water expansion vessels are also available.

- Reduces start/stops of the driving pump , saving energy, maintenance costs and improving lifetime of the pump.

- Ensures constant water flow, even in case of pressure fluctuations.

- Water just flows through this vessel, without stagnation, and keeps its primary quality.

- Absorbs water hammers

- Ensuring smooth operation, protecting other system components.

Achieved benefits for end users

- Efficient system performance

- Clean and safe fresh water

- Prevention of Legionella or other bacteria

- Highly reliable hydraulic system

- Smooth and safe operation

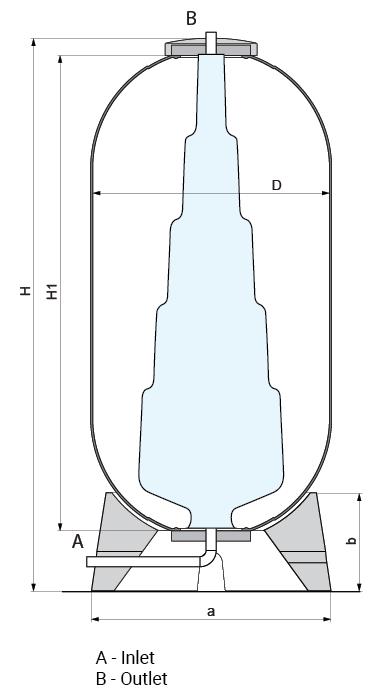

| Composite Expansion Vessels | 310 | 440 | 800 | |

|---|---|---|---|---|

| D (diameter) | (mm) | 620 | 620 | 880 |

| H1 (height) | (mm) | 1300 | 1730 | 1730 |

| H (height) | (mm) | 1500 | 1950 | 1950 |

| a (width) | (mm) | 700 | 700 | 850 |

| b (height) | (mm) | 300 | 300 | 350 |

| Net tank capacity | (l) | 310 | 440 | 800 |

| Approx. weight | (kg) | 60 | 75 | 94 |

| Connection A, B | up to 6/4” | |||

| Max. working temp. | (°C) | 90 | ||

| Max. working pressure | (bar) | 6 | ||

| Max. test pressure | (bar) | 9 | ||