Heat Exchangers

Heat Exchangers

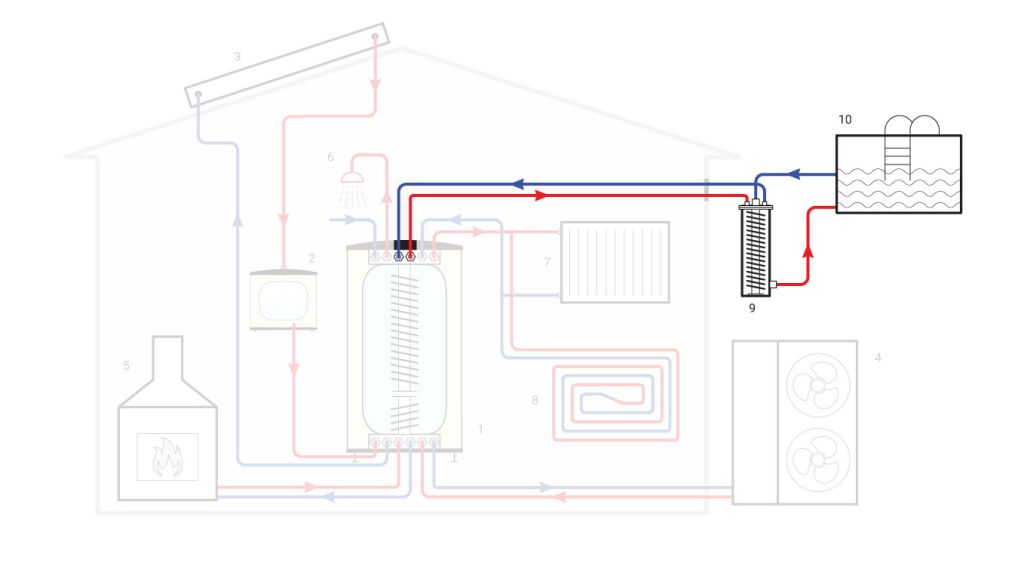

Wide range of applications

- Heat pumps

- Central heating systems powered by various sources of energy

- Pool water heating

- Industrial heat exchange and heat recovery

- Pasteurization in the beverage industry

- Air conditioning

- Production of domestic hot water for baths, showers, laundries, and kitchens

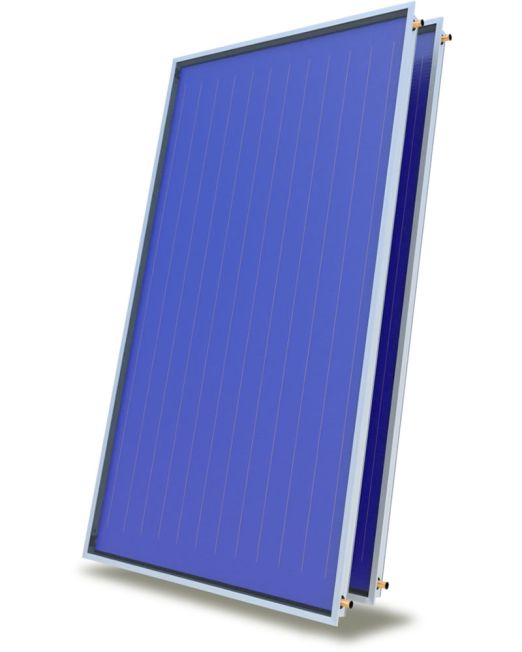

- Solar thermal heating and domestic hot water production

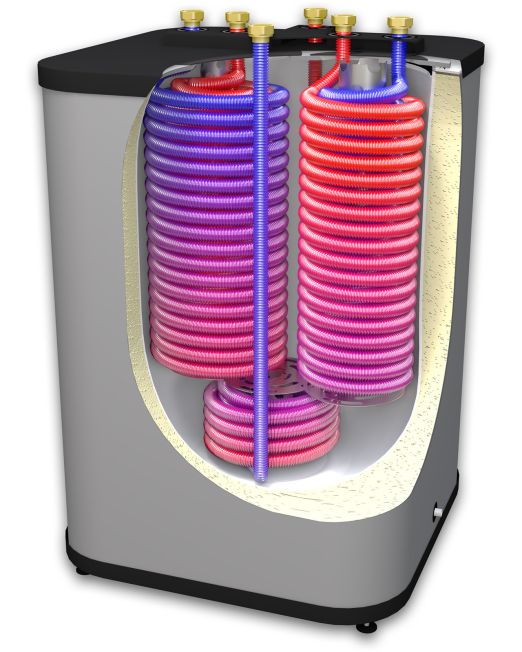

Solarico helical coil heat exchangers were primarily designed for the production of domestic hot water of UniQube storage tanks. In order to get the most efficient hot water production, we put a lot of effort into the research and development of our heat exchangers.

We produced our design of helical coil heat exchanger, by using corrugated stainless steel pipe, as the most compact and efficient one. The tests show that these types of heat exchangers may be produced in various versions and transfer powers, for lots of applications.

Domestic hot water production

The domestic hot water, produced by on-demand principle through Solarico heat exchangers, is hygienic hot water, preventing Legionella and other bacteria proliferation.

Compared to traditional water heaters, producing the hot water on demand, without storing it, Solarico heat exchangers can supply more significant quantities of hot water with up to 40% lower energy consumption.

Self-cleaning, less maintenance

The material used is mirror surface finish Inox 316L. In combination with turbulencies and swirlings inside, the polished surface does not support deposits and limescale. It ensures a constant high performance and minimum maintenance throughout the entire service life.

Custom design

We provide all the experience, knowledge, and manufacturing capacity to our clients for their specific designs and projects. The heat exchangers may be customized to meet the most varied requirements and applications. The length, fittings, and overall dimensions may be customized on request.

Increased heat transfer rate

Corrugated pipe heat exchangers, provide up to 60% improved performance, compared to conventional flat-plate heat exchangers, because of:

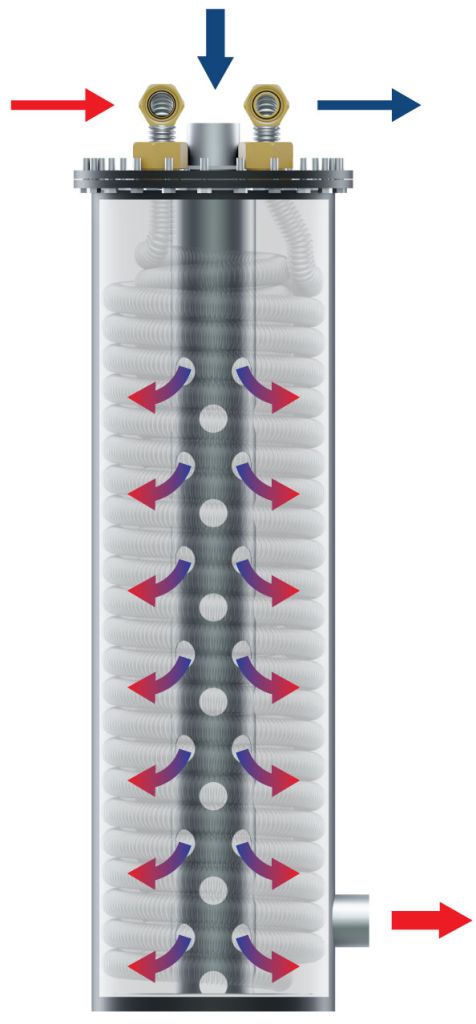

- Innovative fluid dynamics design - There is a stratification tube inside, used in combination with a decentralized inlet and outlet for the pipe-surrounding fluid.

- Geometrical design - Choosing the right helical coil diameter, pipe diameter, and pitch dimensions are crucial to the heat exchanger performance. As the number of turns in the coil increases, the temperature drops of hot fluid also increased. The increase in the number of turns resulted in a higher rate of heat transfer.

- Physics - Pipe corrugations cause continuous disturbance of the boundary layer of the tube side fluid, increase the amount of turbulence, mix the thermal layers, and lower the flow speed in the middle of the pipe. These effects increase the overall rate at which heat is transferred compared to laminar flow heat exchangers.

The stratification tube inside leads the primary fluid into complete contact with the heat transfer surface, improving efficiency by 20%

| Solarico Heat Exchangers - SHE | |||||

|---|---|---|---|---|---|

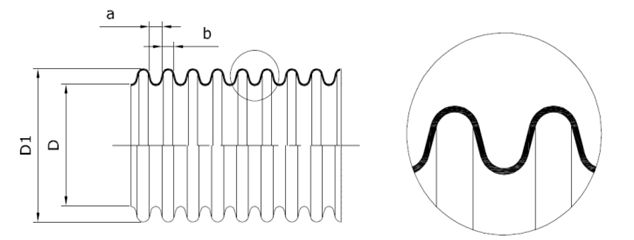

| Corrugated pipe | |||||

| D | (mm) | 25,20 | |||

| D1 | (mm) | 31,60 | |||

| a | (mm) | 3,20 | |||

| b | (mm) | 2,00 | |||

| Tolerance | ±0,30 | ||||

| Operating pressure | (bar) | 11 | |||

| Suface area per meter | (m²/m) | 0,191 | |||

| Min. section area | (mm²) | 498,76 | |||

| Volume | (m³/m) | 0,6335 | |||

| Material | Inox 316L | ||||

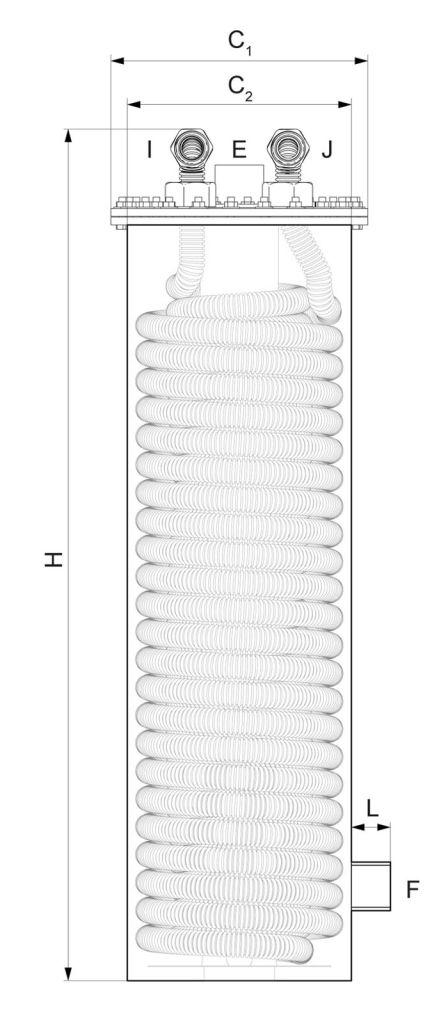

| Heat exchanger | 310U | 310D | 440U | 440D | |

| C1 (diameter) | (mm) | 300 | 300 | 300 | 300 |

| C2 (diameter) | (mm) | 250 | 250 | 250 | 250 |

| H (height) | (mm) | 910 | 380 | 1140 | 600 |

| L (length) | (mm) | 40 | 40 | 40 | 40 |

| Total surface area | (m²) | 5,10 | 1,00 | 6,80 | 1,40 |

| Total pipe length | (m) | 26,50 | 5,00 | 35,50 | 7,50 |

| Total volume | (l) | 14,68 | 4,64 | 19,31 | 7,73 |

| Power (up to) | (kW) | 25 | 7 | 35 | 10 |

| Approx. weight | (kg) | 39 | 22 | 46 | 29 |

| Nominal flow rate | (l/min) | 20 | |||

| Maximum flow rate | (l/min) | 30 | |||

| Connections (E, F) | 6/4" | ||||

| Connections material (E, F) | Stainless steel | ||||

| Connections (I, J) | 5/4" | ||||

| Connections material (I, J) | Brass | ||||

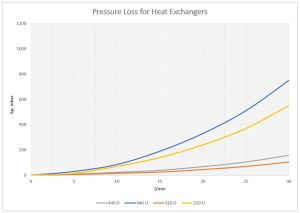

Pressure Loss for Heat Exchangers

Dedication of our expert team have already contributed the implementation of quality standards ISO 9001:2008 and certification of the UniQubes, by TUV Hessen, for complying with Pressure Equipment Directive